(Photo: Iowa Soybean Association / Bethany Baratta)

Journey to the Pacific Northwest

October 1, 2024 | Bethany Baratta

How a port expansion will be a boon to soybean exports

As demand for soybean oil increases as a feedstock for renewable fuels, so, too, does the pile of the co-product, soybean meal. After all, you need the whole soybean to squeeze the oil.

The soybean meal that remains is a highly sought-after commodity among global customers.

Ag Processing Inc (AGP) realizes the opportunity.

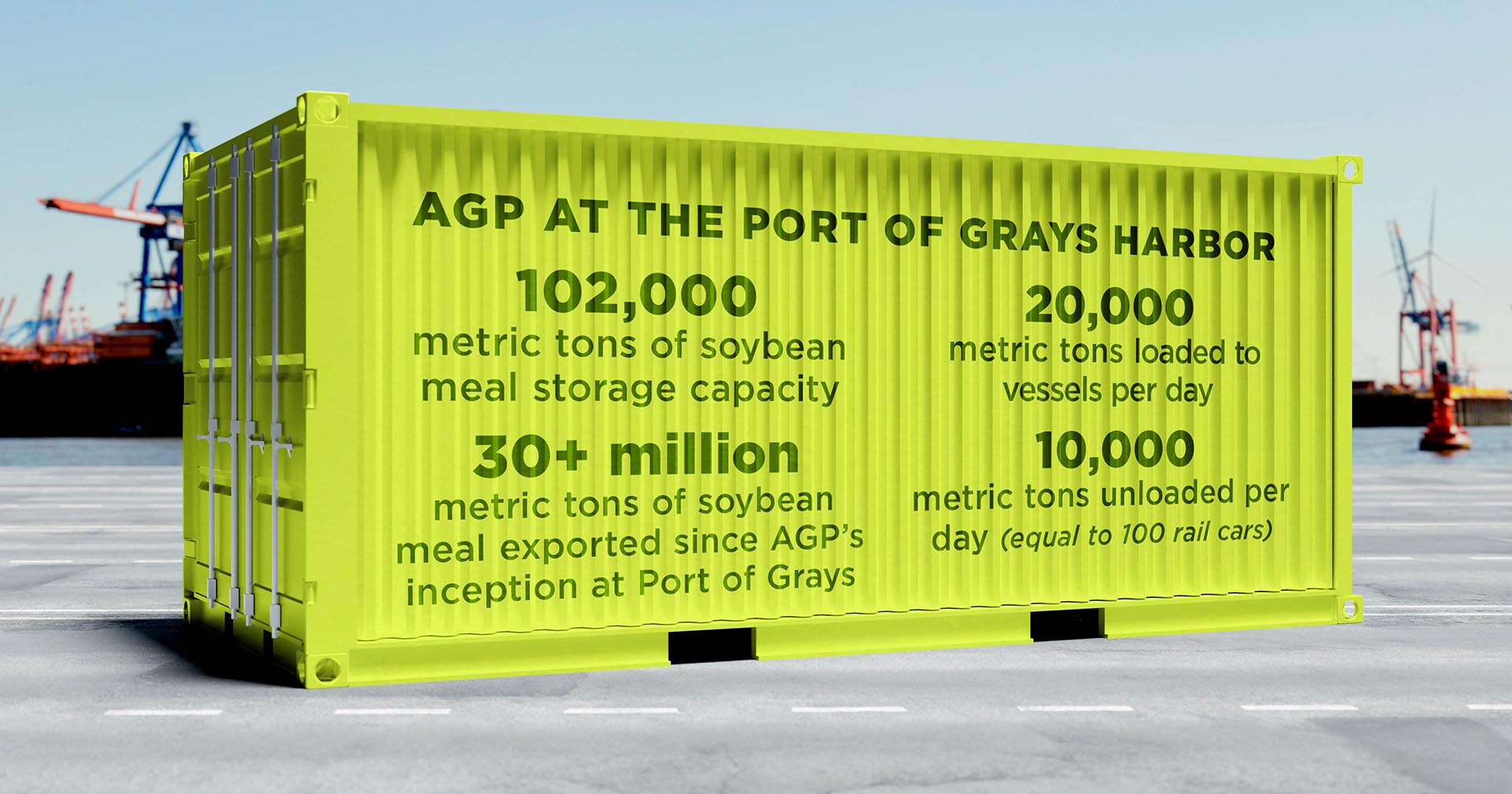

In 2022, AGP approved an expansion and upgrade of its export facilities at the Port of Grays Harbor in Aberdeen, Washington.

The upgrade will double AGP’s capacity — from 3.5 million to 7 million tons — of soybean meal exports annually.

“U.S. domestic demand can’t absorb the additional production resulting from the increase in renewable fuel production, and that’s where Grays Harbor comes in,” says Craig Pietig, vice president of ag products for AGP. “We can push this product into the export channels to feed the growing demand, but also compete with the other origins for this market share that we’re going to need going forward.”

AGP will upgrade its current facilities at Terminal 2, including the construction of additional storage. It will also add a new state-of-the-art ship loader at the harbor’s Terminal 4. Terminal 2 and Terminal 4 are both deep-water berths with quick access to the open ocean. The planned expansion will enable AGP to load multiple ships up to and including Panamax-sized vessels.

To accommodate this upgrade, the Port of Grays Harbor needed to expand its terminal to accommodate this growth for its largest customer, AGP. The Port of Grays Harbor was awarded a $25.5 million Port Infrastructure Development Program grant from United States Department of Transportation Maritime Administration for its Terminal 4 expansion and redevelopment project. It was matched with $21.35 million in non-federal funds.

Seeing the opportunity to expand soybean exports globally, the Soy Transportation Coalition (STC) brought together farmer-leaders to explore how STC could support the project.

“It was one of the first ways for us to lean into the expected increase in crush and say, ‘What are we going to do with all this meal?’ Here, we’re willing to invest in something that will actually move it onto the export market,” says Mike Steenhoek, executive director of the STC, which works to promote a cost effective, reliable, and competitive soy transportation system.

The Iowa Soybean Association, Kansas Soybean Commission, Nebraska Soybean Board, North Dakota Soybean Council, South Dakota Soybean Research and Promotion Council, STC and the United Soybean Board collectively contributed $1.3 million to the Terminal 4 expansion and redevelopment project. The money helps offset pre-engineering, design and site development costs, which will add 40,000 feet of additional rail within its Marine Terminal Complex, a new fendering system and a stormwater collection and treatment facility at T4. It will create more than 30 acres of additional cargo laydown area to support future operations at Terminal 4A.

“We can produce more than we use in the United States, so we have to find a customer somewhere else,” says ISA District 8 Director Warren Bachman, who serves on the STC Board. “But it doesn’t do any good to have a customer if we can’t get the product from our driveway to their location. So anything we can do to facilitate the movement of our products is money well spent.”

Bachman joined farmers from other soy-producing states to see the site of the planned project. The tour gave ISA District 7 Director Scot Bailey another perspective on the journey his soy takes from his farm near Anita to the AGP facility in Council Bluffs to the Pacific Northwest and to customers around the world.

“It is very eye-opening for a farmer to come out and just see what everybody is doing out here to help us market our grain more efficiently,” says Bailey, who represents ISA on the STC board.

“These companies are helping us at harvest time, being able to move our grain to keep the system moving. If we bottleneck at the elevator locally and can’t get out to the crushers, that bottlenecks the whole system. This avenue of having them move product to keep everything flowing during harvest makes a lot of difference. It reduces the storage capabilities we need in the Midwest during harvest.”

The $1.3 million helps in the early stages of the project, which is expected to be completed in 2026.

“This contribution aided this transformative project during a critical point,” says Port of Grays Harbor Executive Director Leonard Barnes, who has now worked at the port for 40 years. “But this project isn’t just about Grays Harbor. This project is about all of you — the farmers — and the transportation of a global food source. And we can’t thank you enough for having the confidence in AGP, our Port, and this project to step up and be willing to play such a role.”

Back