(Photo: Iowa Soybean Association)

Using woodchip bioreactors to reduce nitrate loss

April 29, 2025 | Alex Buseman

Tile drainage and nitrate (NO3) inputs have developed Iowa into an agricultural powerhouse by enabling the production of crops that feed and fuel the world. While beneficial for agricultural productivity and profitability, the combination has contributed to exports of NO3 into the surrounding environment. This can lead to challenges with drinking water sources and harmful algae blooms in aquatic ecosystems, justifying the need for edge-of-field water quality practices such as woodchip bioreactors.

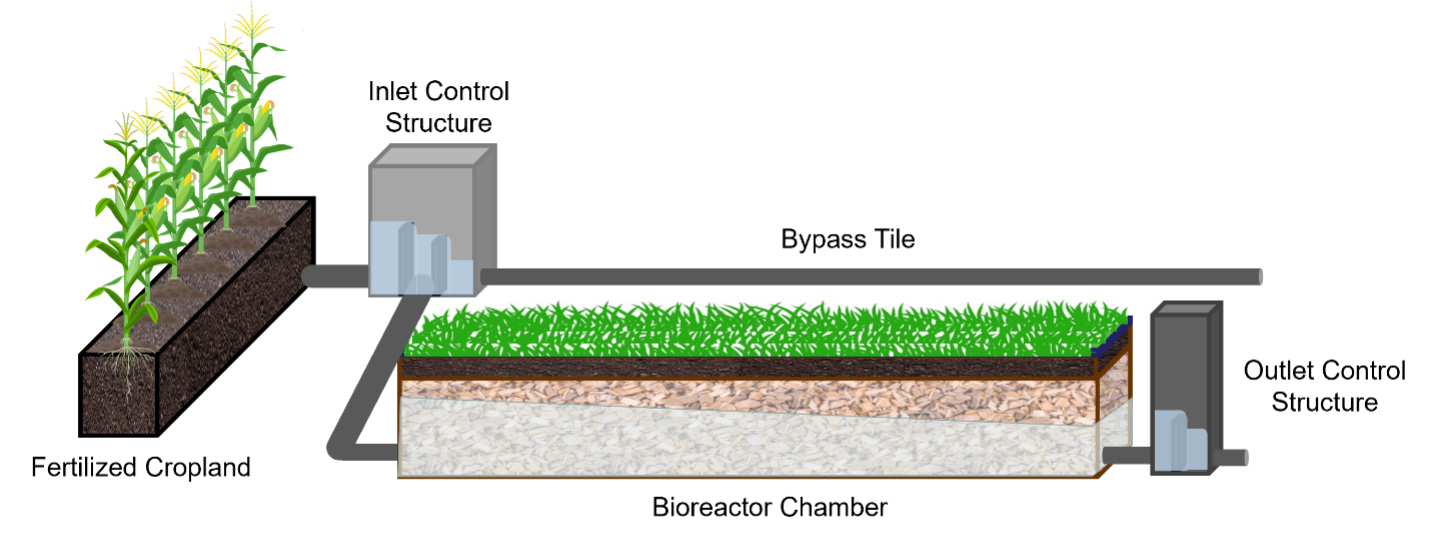

Woodchip bioreactors divert tile flow into an underground, woodchip-filled chamber. Within the chamber, denitrifying bacteria naturally establish communities due to favorable conditions.

These bacteria remove the excess NO3 in the diverted tile water through a natural process called denitrification. This process is comparable to humans consuming food as fuel and respiring oxygen (O2) in the atmosphere, the denitrifying bacteria use the woodchips as fuel and respire the oxygen in the NO3.

The denitrifying bacteria use the carbon in the woodchips as fuel and respires the oxygen in the NO3. The denitrification process reduces the NO3 to nitrogen gas (N2), which is a harmless gas that makes up 78% of our atmosphere.

Research shows bioreactors remove 43% of NO3 in tile water on average. Because of this success, they were added in the Iowa Nutrient Reduction Strategy as an official practice in 2013.

This practice is viable because it operates with minimal human input, can be installed in almost any landscape with tile drainage and has minimal impact to in-field farming operations.

Assessing performances

The performance of bioreactors is assessed by their ability to remove NO3 from tile water and effectively conduct flow through the woodchip-filled chamber. Nitrate removal in bioreactors is assessed by measuring the NO3 content in the inlet and outlet control structures to calculate the removal efficiency. Flow is another important factor we inspect because the system’s design is ineffective if flow through the chamber becomes restricted.

Like all things in life, the performance of bioreactors decreases as they age. Most research investigating bioreactor longevity was done in lab-controlled settings, meaning they were not subject to environmental factors such as freeze-thaw cycles and wet-dry cycles that might accelerate woodchip degradation.

Additionally, sediment clogging and woodchip compaction could decrease a bioreactor’s longevity

by restricting flow.

Research results and implications

Most lab studies suggest bioreactors can last 10 to 15 years. ISA and its partners sought to expand this research to field-scale bioreactors by recruiting 10 Iowa farmers with aged bioreactors. Each site had a history of monitoring which enabled us to examine how performances changed over time. Out of all 10 bioreactors, three were in failing condition. Failing condition is defined as average NO3 removal efficiencies less than 30% for an entire drainage year and/or indications of restricted flow. Two sites exhibited NO3 removal below the 30% threshold, while one bioreactor showed extreme sediment clogging restricting the flow. The remaining sites were still operating effectively at extended ages, with the oldest original site in Iowa still operating above average (>50% NO3 removal) after 16 years of operation.

This study indicated the lifespan of bioreactors can vary from site to site and does not depend on their age. The results show that 70% of bioreactors can effectively operate beyond 10 years. Farmers can help extend their bioreactor’s longevity with good management practices such as:

- Minimizing traffic on top of the chamber to reduce compaction potential

- Maximizing saturated conditions by keeping stoplogs in the control structure to limit woodchip degradation

- Be vigilant about sediment sources and clogging potential

When bioreactors reach failing conditions, the old woodchips are excavated and replaced with new woodchips; essentially installing a new bioreactor and resetting its lifespan. ISA is currently partnering with the landowners with the failing aged bioreactors from this study to do a woodchip recharge.

Woodchip bioreactors have become a popular water quality practice in Iowa, with more than 200 installations. Reach out to ISA’s edge-of-field experts, Alex Buseman at abuseman@iasoybeans.com and Brandon Iddings at biddings@iasoybeans.com, with questions regarding water quality practices on your farm.

Back